Table of Contents

- Understanding the Importance of Choosing the Best Blades for Your Oscillating Tool

- Types of Blades Available for Oscillating Tools and Their Specific Uses

- Top Factors to Consider When Selecting the Best Blades for Your Oscillating Tool

- (Our Recommendations) 5 Best Oscillating Tool Blades on the Market Today

- Tips and Tricks for Maintaining and Extending the Lifespan of Your Oscillating Tool Blades

- Oscillating Tool Blades FAQs

Discover the ultimate guide to selecting the perfect blades for your oscillating tool. Learn about different types, materials, and sizes to ensure you have the right blade for any project. Upgrade your cutting precision today with our comprehensive blade selection tips.

Understanding the Importance of Choosing the Best Blades for Your Oscillating Tool

When it comes to your oscillating tool, the blades you choose can make all the difference. The best blades for your oscillating tool can significantly impact the quality of your work and the efficiency of your projects.

Investing in top-quality oscillating tool blades is crucial for achieving precise cuts, smooth finishes, and overall better results. Whether you're working on wood, metal, or other materials, having the right blade for the job is essential.

Don't overlook the importance of selecting the right multi-tool blades for your oscillating tool. These accessories can enhance versatility and performance, allowing you to tackle a wide range of tasks with ease. By choosing high-quality blades that are suitable for your specific needs, you can maximize the potential of your oscillating tool and achieve professional-level results.

Types of Blades Available for Oscillating Tools and Their Specific Uses

When it comes to oscillating tools, having the right blade for the task at hand can make all the difference in the world. There are various types of blades available, each designed for specific uses.

- Wood Cutting Blade: Ideal for cutting through wood materials with ease, these blades are designed to deliver clean and precise cuts. They come in various sizes to accommodate different wood thicknesses.

- Metal Cutting Blade: For cutting through metal surfaces, a metal cutting blade is essential. These blades are constructed with materials that can withstand the toughness of metal, providing smooth and accurate cuts.

- Tile Cutting Blade: When working on tile installations or repairs, a tile cutting blade is indispensable. These blades are crafted to cut through ceramic, porcelain, or other types of tiles cleanly and without chipping.

- Grout Removal Blade: Removing grout can be a tedious task without the right tool. A grout removal blade attached to your oscillating tool makes this job much more manageable by efficiently clearing out old grout lines.

- Sanding Pad Attachment: In addition to cutting tasks, oscillating tools can also be equipped with sanding pad attachments for smoothing surfaces or removing paint or rust from various materials.

Having a variety of blades for your oscillating tool allows you to tackle different projects effectively and achieve professional results in woodworking, metalworking, tiling, grout removal, and surface finishing tasks.

Top Factors to Consider When Selecting the Best Blades for Your Oscillating Tool

When selecting the best blades for your oscillating tool, there are several key factors to consider.

Durability is a crucial aspect to keep in mind. Look for blades made from high-quality materials that can withstand tough materials and extended use without losing their sharpness.

Compatibility is another important factor. Ensure that the blades you choose are compatible with your specific oscillating tool model to avoid any issues during operation.

Consider the blade material as well. Different materials are suitable for cutting through various surfaces, so select a blade material that aligns with the type of projects you typically work on.

The teeth per inch (TPI) of the blade also play a significant role in its performance. Higher TPI blades provide smoother cuts on softer materials, while lower TPI blades are better suited for tougher materials.

Lastly, take into account the brand reputation when choosing blades for your oscillating tool. Opt for reputable brands known for producing high-quality and reliable tools and accessories to ensure you get the best results.

5 Best Oscillating Tool Blades on the Market Today

- Top Shelf - Vtopmart 50 Wood Oscillating Multi Tools Quick Release Saw Blades (overview)

- Next Best - EZARC Oscillating Saw Blades, Carbide Multitool Blades (overview)

- Editor’s Choice - 100 Pcs Oscillating Tool Blades,Professional Universal Oscillating Saw Blades (overview)

- Consumer Favorite - Vtopmart 20 Metal Wood Oscillating Multitool Quick Release Saw Blades (overview)

- Best Bang For Your Buck - EZARC Titanium Oscillating Multitool Blade for Wood Metal - 3-Pack Oscillating Tool Saw (overview)

TOP SHELF

Top Shelf Features

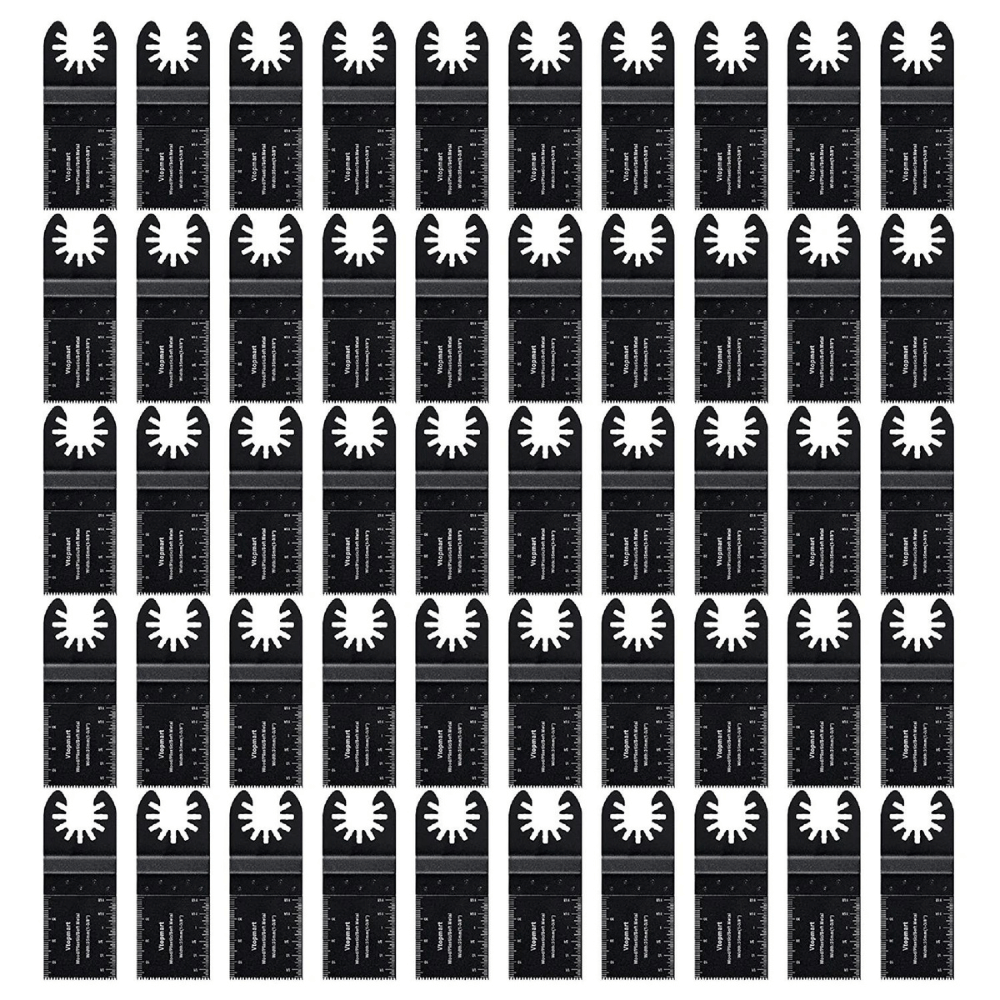

The Vtopmart 50 Wood Oscillating Multitool Quick Release Saw Blades comprise a set of 50 oscillating tool blades, suitable for cutting wood, plastic, and metal.

The brand Vtopmart manufactures these blades, which come in black. Designed to be compatible with wood, plastic, and metal materials, they are suitable for a variety of tasks and settings, including workshops and households.

These blades are also compatible with many oscillating tools, excluding the Bosch MX30, and come with a 100% satisfaction guarantee from the manufacturer.

Top Shelf Details

The blades are manufactured using special techniques and thick-gauge metals, contributing to their durability. They also feature built-in length markers on two sides, one in inches and the other in centimeters, enabling easy and accurate cuts.

The Superior Value Oscillating Saw Blades kit is compatible with numerous oscillating tools on the market, including Fein Multimaster, Ryobi, Milwaukee, Hitachi, Black & Decker, Chicago, Craftsman, and more. However, it does not support Bosch MX30 oscillating tools.

Next Best

Top Shelf Features

The EZARC Oscillating Saw Blades are a set of multi-tool blades with carbide teeth, designed for high performance in metal and other materials.

Carbide is a durable material that can endure heavy use and wear. These blades, designed for high performance, excel in cutting metal and other materials, making them an excellent choice for tasks requiring precise and efficient cuts.

These blades are suitable for use with a range of oscillating tools. They come in a variety of sizes and shapes to meet different cutting needs.

Top Shelf Details

These metal blades are suitable for cutting through a variety of materials, including stainless steel, hardened screws, nails, bolts, fiberglass, and plasterboard.

These blades, manufactured by the brand EZARC, have dimensions of 1.38 x 0.39 x 3.43 inches. They come in a 3-piece set, each blade weighing approximately 30 grams. With an industrial style, they are presented in a distinct color.

They are an excellent choice for tasks requiring high performance and durability.

Editor's Choice

Top Shelf Features

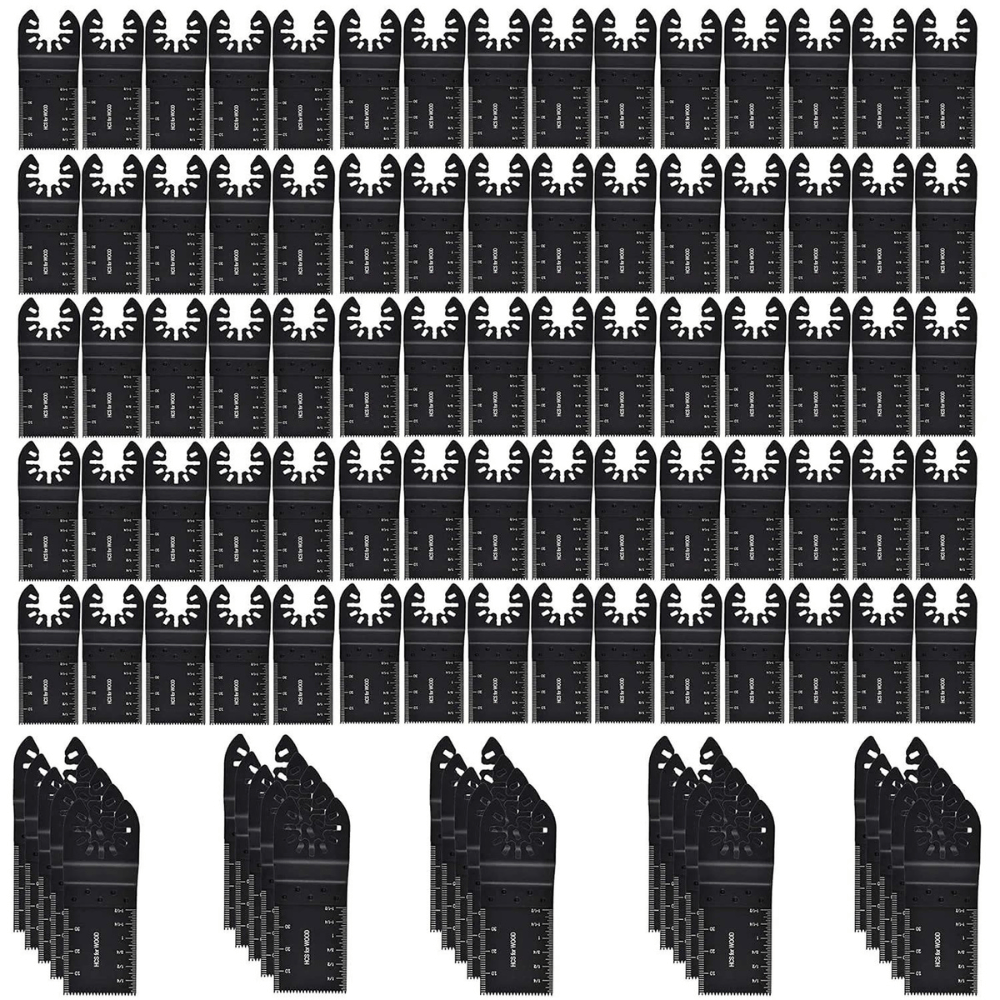

The Professional Universal Oscillating Saw Blades are a set of oscillating tool blades designed to make cutting tasks more efficient.

They are part of a high-value kit that includes 100 packs of blades, offering a plentiful supply for various projects. These blades are compatible with many oscillating tools on the market, such as Fein Multimaster, Ryobi, Milwaukee, Hitachi, Black & Decker, Chicago, Craftsman, and more, but not with Bosch MX30.

Their quick-release feature allows for effortless switching between different blade types based on the task at hand. Designed for high performance and durability, these blades are an excellent choice for a wide range of cutting tasks.

Top Shelf Details

The Professional Universal Oscillating Saw Blades, manufactured by MinCHI257, are a versatile set suitable for cutting various materials, including wood.

Available in black, these durable blades are designed to deliver precise and efficient cuts. The set includes 100 pieces, ensuring a plentiful supply for numerous projects. Compatible with a range of oscillating tools, they are an exceptional choice for tasks demanding high performance and durability.

Consumer Favorite

Top Shelf Features

The Vtopmart 20 Metal Wood Oscillating Multitool Quick Release Saw Blades are designed for use with oscillating multitools. Crafted from high-quality materials, these blades are durable and long-lasting. Their standout feature is the quick-release design, enabling easy and convenient blade changes. They are compatible with various oscillating multitools, including those from brands like Bosch, Fein, Dremel, Craftsman, and more.

Top Shelf Details

These blades allow for precise cuts, and their special design featuring longer wavy teeth is specifically crafted to ensure faster, cleaner cuts in wood and plastic. They are suitable for cutting through various materials and are compatible with many oscillating tools on the market. These blades are an excellent choice for tasks demanding high performance and durability.

Best Bang for Your Buck

EZARC Titanium Oscillating Multitool Blade for Wood Metal - 3-Pack Oscillating Tool Saw Blades

Top Shelf Features

EZARC Titanium Oscillating Multitool Blades are specialized tools designed for a range of general cutting applications. Constructed from high-quality titanium, these blades are robust and durable, capable of handling even the toughest materials. They are particularly noted for their precision cutting capabilities.

Besides, this blade is renowned for its versatility and durability. The titanium construction ensures that the blade can withstand heavy use, making it a reliable choice for both professionals and DIY enthusiasts.

Top Shelf Details

This blade is a high-quality tool designed for various general cutting applications. Crafted from durable titanium, it is strong and wear-resistant, making it a reliable choice for both professionals and DIY enthusiasts. The EZARC brand, known for producing top-quality tools and multi-tool accessories, proudly presents the Titanium Oscillating Multitool Blade.

With dimensions of 6.22 inches in length, 3.86 inches in width, and 0.91 inches in height, this compact blade is easy to handle. Weighing a mere 20 grams, it is lightweight and convenient to use.

This blade is compatible with a wide range of materials, including wood, wood with nails, plastic, brass, aluminum, and copper. Its unique tooth geometry enables clean and precise cuts in these materials, making it a versatile tool for various cutting tasks.

The blade comes in a pack of three, providing plenty of replacements when needed. Whether you're a professional contractor or a DIY enthusiast, this blade is an essential tool for anyone requiring a reliable and efficient cutting instrument.

Tips and Tricks for Maintaining and Extending the Lifespan of Your Oscillating Tool Blades

To ensure the longevity of your oscillating tool blades, proper maintenance is key. Regularly cleaning your blades after each use can prevent debris buildup and corrosion. Additionally, sharpening your blades when they start to dull can extend their lifespan significantly.

When sharpening oscillating tool blades, make sure to use the appropriate tools and techniques. You can use a file or a sharpening stone to carefully sharpen the blade edges. Remember to maintain the original angle of the blade while sharpening for optimal performance.

Proper storage of oscillating tool blades is also crucial in maintaining their quality. Store them in a dry environment to prevent rust and corrosion. Using blade covers or cases can further protect them from external damage and ensure they remain sharp for longer periods.

By following these simple tips and tricks for maintenance and storage, you can maximize the lifespan of your oscillating tool blades and save on replacement costs in the long run.

Best Oscillating Tool Blades for You

In conclusion, oscillating tool blades are essential accessories for any professional or DIY enthusiast. They come in a diverse range of types and sizes, each designed for specific tasks and materials.

Choosing the right oscillating tool blade for your needs can significantly enhance your work's efficiency and quality. We trust this article has clarified the various types of oscillating tool blades and guided you in selecting the best one for your project.

Click or tap the buttons to check the price on the one that best fits your needs!

TOP SHELF RECAP

- Top Shelf - Vtopmart 50 Wood Oscillating Multi Tools Quick Release Saw Blades

- Next Best - EZARC Oscillating Saw Blades, Carbide Multitool Blades

- Editor’s Choice - 100 Pcs Oscillating Tool Blades,Professional Universal Oscillating Saw Blades

- Consumer Favorite - Vtopmart 20 Metal Wood Oscillating Multitool Quick Release Saw Blades

- Best Bang For Your Buck - EZARC Titanium Oscillating Multitool Blade for Wood Metal - 3-Pack Oscillating Tool Saw

Oscillating Tool Blades FAQs

Here are the most frequently asked questions about the best oscillating tool blades:

Are all oscillating tool blades the same?

No, definitely not! Oscillating tool blades come in a variety of sizes and shapes, each designed for different uses. While they usually share a basic shape - typically a wedge-shaped cutting edge on one side and a flat, blunt backing on the other - their size, material, teeth configuration, tooth pitch (spacing), and depth significantly vary according to their intended job.

For instance, wood-cutting blades typically have smaller teeth set closer together than those of metal-cutting blades. They're also generally thinner, allowing them to cut through wood fibers without causing excessive damage. Conversely, metal-cutting oscillating tools require larger teeth with wider spaces between them to cut through metal effectively without getting clogged. These blades are usually thicker to prevent bending or breaking when used against hard surfaces like steel beams or ceramic tiles.

In short, there is no universal oscillating tool blade as each job demands specific sizes and shapes for optimal performance, efficiency, and user safety. Different motors also require unique accessories for proper functioning. Always refer to the manufacturer's information for compatibility before purchasing new oscillating tool blades or related accessories/attachments.

What can you cut with an oscillating tool blade?

An oscillating tool blade is a highly versatile cutting instrument, capable of handling a variety of tasks. It provides swift and effortless cuts through materials such as wood, plastic, metal, and more. Here are some of the many things you can cut with an oscillating tool blade:

Wood: If you're engaged in any type of carpentry work involving wood, an oscillating tool blade is indispensable! It allows you to easily make tight straight cuts in all types of lumber - both hardwoods and softwoods. Its versatility enables detailed cuts like notches or the creation of curved shapes.

Tile & Grout: An oscillating tool quickly removes tile from countertops or floors by swiftly slicing through grout with its specialized blades. This makes it ideal for remodeling projects involving tiling around sinks or tubs, or even for general bathroom renovations!

Plastic & Metal: Oscillating tools can power through thick layers of metals, like aluminum siding and steel framing pieces, which would typically require saws. They also excel at cutting into plastic pipes without deforming them, making it easy to reroute plumbing pipes while minimizing the mess caused by other methods!

Nails & Screws: With its rapid-fire action, an oscillation blade easily slices through nails and screws embedded in materials like drywall or deck boards, ensuring minimal damage to nearby surfaces during demolition tasks. It's particularly useful for electrical repairs, as it eliminates the need to clumsily use a hammer to pry apart wires without causing further damage!

Overall, the possibilities are nearly endless with your reliable oscillating blade! Whether you're a contractor aiming to finish products quickly and effortlessly, or a DIY enthusiast tackling home improvement projects, there's always something for everyone who needs one of these versatile tools in their arsenal!

Can you sharpen oscillating tool blades?

Absolutely! Oscillating tool blades are incredibly versatile and can be honed to enhance performance.

Sharpening your oscillating tool blades is an effective method to protect them from wear and tear, ensuring their longevity. While you can buy replacement blades, self-sharpening is straightforward and often more cost-effective.

There are several techniques for sharpening an oscillating tool blade, so let's dive in!

The first step is to remove any dirt or buildup from the blade - wooden toothpicks are one of the best tools for this task. Ensure you remove all the gunk; excessive buildup on your saw blades can significantly affect their performance!

Once that's done, find two stones - ideally a rough stone (about 400-600 grit) and a finer stone (1000+ grit). Wet both stones in water before starting your sharpening process with the coarse stone. Begin making small circles against the metal until no trace of rust or corrosion remains on the surface; then use your fine stone to sharpen any dull areas that need attention. Remember to apply light pressure at this stage! Depending on the original condition of your saw blade, this process may take some time - but continue until it looks clean and smooth again.

Finally, finish off by using a leather strop with a polishing compound applied to it (a rubbing compound will suffice if you don't have any polishing compound handy). This helps remove minor burrs caused by the abrasive material used during honing, while also adding an extra polish that seals in moisture, providing additional protection against rust over time. It also creates a smoother cutting edge, reducing friction between edges, which improves the overall user experience when operating oscillation tools such as jigsaws or power planers.

Is an oscillating multi-tool worth it?

In my opinion, owning an oscillating multitool is absolutely worth it! These tools not only offer a multitude of capabilities for various projects around the house or garage, but they also provide greater efficiency and precision than standard tools.

Oscillating multitools are extremely versatile equipment that can be used for cutting, grinding, sanding, scraping, and polishing. They can handle almost any DIY project - from cutting baseboards to grinding stubborn grout or even polishing your car. The oscillation action provides control over the depth of your cuts and offers greater accuracy than a standard tool. This makes them perfect for detailed projects like intricate carpentry on furniture or precisely trimming windowsills.

An oscillating multitool can save time, typically completing jobs in one-fifth the time of traditional power tools. Besides being efficient, multitools are often cordless, providing total freedom when working away from main power outlets. This eliminates the need to stretch extension cords across the room to reach your project area.

Can oscillating tools cut through nails and screws?

Absolutely! Oscillating tools are designed to cut through even the toughest materials, such as nails and screws, making them suitable for a variety of tasks. They're excellent for detailed jobs requiring precision, like cutting through trim or removing rust from metal surfaces.

The secret lies in the oscillating motion, which powers through nails and screws with ease. The tool's blade moves back and forth rapidly at high speeds, enabling incredibly precise cuts without putting too much strain on your arms or wrists. When using an oscillating tool to cut through nails or screws, it's best to proceed slowly to avoid damaging nearby objects, such as walls, with flying nail shavings.

Can you polish using an oscillating tool?

Yes, you absolutely can polish with an oscillating tool!

When using an oscillating tool for polishing, ensure to follow these steps:

1. Attach a sandpaper pad to your oscillator attachment. If you are working on metal surfaces, start with a grit slightly higher than 200 (220-240 grit). For softer surfaces like wood or plastic, use 120-150 grit paper.

2. Apply light pressure and move the sanding pad in small circles over the area you're polishing. Avoid staying in one spot too long to prevent damage from excessive heat build-up, caused by the friction of the pad against the surface material.

3. Swap your sandpaper pads until you achieve the desired results. Smooth rough areas before starting the final polish stages, which will involve finer grades of paper, ranging from 600 to 1500+.

4. Depending on the extent of polishing required, you might want to add motor oil directly to your abrasive papers. This can help reduce adhesion problems when cleaning surfaces. It also acts as a lubricant, protecting against heat buildup during extended use and preventing potential thermal distortion issues that could arise from improper techniques during longer work sessions..